Share article:

Tags:

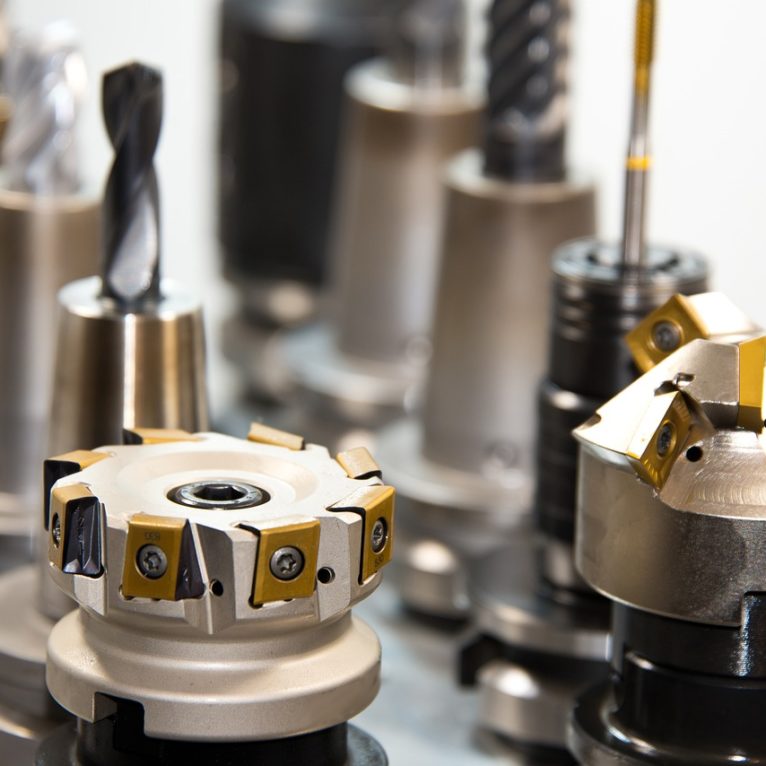

Machine vision has long been associated with manufacturing, with scope to assist with a range of applications, including quality control, automation and safety in the production process. It’s a versatile and robust technology that has become an integral part of modern manufacturing.

More recently, neural network models have become commonplace in the industry, as accurate and efficient tools that can be used to simulate manufacturing processes. Many industrial plants have adopted convolutional neural networks (CNNs) to optimise manufacturing processes. AI based vision technologies are enabling the next generations of smart factories

As the key to machine vision being useful is accuracy, ensuring that models are trained on large, representative datasets is critical. There are infinite combinations of lighting, objects, occlusions and other factors that can make gathering the correct imagery difficult.

As you can imagine, obtaining large amounts of training data can be a challenge.

Synthetic training data has emerged as a solution to this problem and as a result, is revolutionising the manufacturing industry.

It has several advantages over traditional training data. It can be generated quickly and at scale, which is particularly useful in industries where obtaining real-world data is expensive or difficult. Synthetic data can also be used to create data that is difficult or dangerous to obtain in the real world, such as simulating scenarios where personnel enter restricted areas that are too close to operating machinery, that would be impossible to do safely in the real world.

Japan Leading the Way

Japan is a leader in adopting AI and other digital technologies for quality control in the manufacturing industry. It is an essential component of the long-standing reputation for excellence in Japanese manufacturing, and the use of AI has sky-rocketed in recent years.

Companies are developing high-quality training data sets for AI and machine learning, tailored to meet the specific needs of the manufacturing industry. Designed to improve the accuracy and efficiency of quality control processes, this approach is enabling companies to optimally identify defects, in turn achieving high quality products and increased operational efficiency. By investing in these technologies, Japanese manufacturers are positioning themselves at the forefront of innovation, ensuring their continued success in the global marketplace.

Applications in the Automotive Industry

Traditionally, the automotive industry has been a heavy user of synthetic data to train driver assistance systems and help to develop AI models that can detect potential hazards and improve safety. By accurately simulating real-world driving scenarios, models can be trained to identify potential hazards in a safe and controlled environment. Additionally, synthetic training data is also being used in the inspection of metal parts for defect identification, with benefits of greater speed and accuracy over traditional methods.

But now new applications are emerging beyond just assembly line production. Due to the visual fidelity “photo-realism” offered by Chameleon, our end-end platform for synthetic data creation and curation, new applications are emerging. For example, using Chameleon to test where camera and lighting are optimally placed. Utilizing Chameleon’s unique multi camera technology, which allows simultaneous scenario capture from large numbers of cameras (100’s of cameras may be deployed in this type of scenario), enables our end users to get a unique perspective on the visualization of their environment that was previously unavailable to them. As discussed, machine vision’s success is dependent on its accuracy and with these improved capabilities, applications will only grow from here.

Health and Safety

One example of how Mindtech technology can be applied in the manufacturing sector is in the area of health and safety. Specifically, synthetic data can be leveraged to simulate various hazardous scenarios, such as high-heat environments, chemical spills, and exposure to hazardous materials, where personal protective equipment (PPE) is necessary.

By training AI models on this synthetic data, companies can ensure that workers are properly equipped with the appropriate PPE for the job, thereby reducing the risk of accidents, injuries, and exposure to harmful substances.

In the construction industry, this technology can be used to train workers to understand how to use PPE correctly. This can also include helmets, glasses, harnesses and hi-vis gear. These simulations can replicate real-life scenarios that are difficult to create without compromising safety or delaying the project. For instance, in the case of an emergency, AI technology can be utilised to provide 24×7 monitoring and alert human inspectors when intervention may be necessary.

Additionally, simulations can be created to simulate scenarios, such as high-altitude construction, which may be challenging to replicate in real-life environments. In such cases, the use of synthetic data is particularly valuable as it can enable workers to be trained safely and effectively while also ensuring that they have the necessary skills to carry out their tasks effectively.

As the adoption of AI continues to grow, the use of synthetic training data will become increasingly important for the manufacturing industry. This game-changing technology will ensure that AI models are both accurate and unbiased, to drive effective decision-making for years to come.

How Synthetic Training Data is Revolutionising the Manufacturing Industry was originally published in MindtechGlobal on Medium, where people are continuing the conversation by highlighting and responding to this story.